Pietribiasi Michelangelo S.r.l. manufactures machines and complete lines for the dairy industry and for the production of fruit juices and soft drinks, ice cream and beer.

Over time, our market has become international and the company established itself in the food industry with its core products: machines and complete lines for the processing of ice cream mixture, the production of pasteurized and aseptic beverages and the transformation of raw and powder milk into fermented products, cheese, drinking milk, UHT milk and all milk derivates.

Address

Via del Progresso 12

Italy

Products

Our Mixing and Blending Station is designed to ensure a highly efficient mixing and blending process for juices and beverages. Equipped with advanced technology and innovative design, this system allo

…

Inside The Pasteurizer, the product runs through a temperature path, or thermal profile, which eliminates the bacteria and other microorganisms, thanks to a thermal shock which allows to increase the

…

The CIP (Cleaning in Place) system is used to perform the cleaning of equipment such as machinery, piping, and tanks.Each CIP system is custom-designed based on a personalized assessment according to

…

The ice cream preparation plant is a machine used for mixing and preparing the base of the ice cream, before the pasteurization and freezing process. This plant usually includes ingredient dispensers,

…

Fat and raw material dissolvers are key components of the ice cream production plant. These devices are designed to dissolve and amalgamate ingredients such as fats, oils, and powders (for example, mi

…

A batch plant for the production of ice cream mixture is a system designed to mix, pasteurize and cool the mixture before freezing. The mixture is pasteurised in a heating vessel at controlled tempera

…

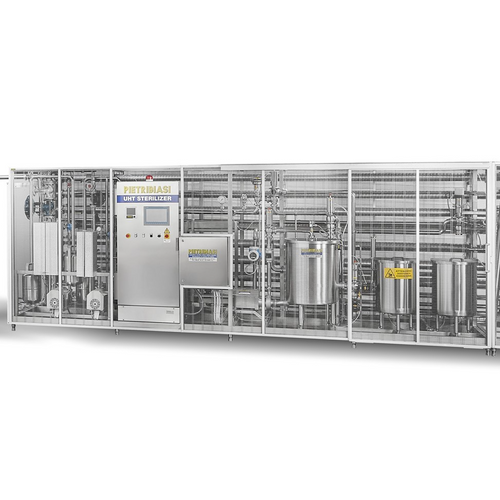

The aseptic plant is a storage tank for the sterilized product and is used between the processing and the filling sections.

UHT (Ultra High Temperature) milk is treated through a process of rapid, indirect heating, reaching temperatures of at least 135 °C for a few seconds, followed by immediate cooling to room temperature

…

Pasteurization consists of submitting milk or other liquid foods to a thermal shock which destroys a great part of its bacterias. This process allows to increase the shelf life of pasteurized products

…

Brands

Pietribiasi Michelangelo S.r.l. is a leader in producing top-quality machines and complete lines for the dairy industry, ice cream, fruit juices, soft drinks, and beer. We focus on the national and in

…

Press Releases

Machines and complete lines for the production of pasteurized and aseptic beverages. For Instance: a full automatic blending stations for drinks juice preparation and mixing.

Customized pasteurization lines for cheese, fresh milk, fermented products, cream, full automatic version with CIP on board.

)

)

)