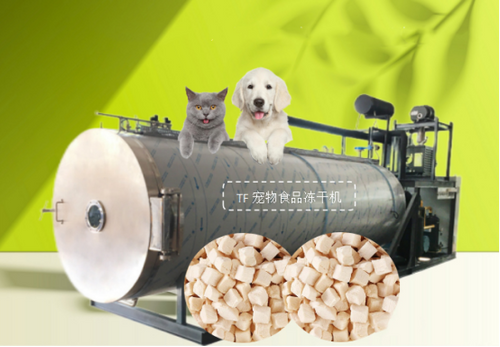

Freeze-dried production process of diced chicken breast pet food

Freeze-dried production process for diced chicken breast pet food.

First, the fresh chicken breasts will be cut into uniform cubes. The use of professional meat cutting equipment can ensure that the meat is cut into diced meat with uniform and regular shapes, such as the horizontal fresh meat dicing line.

These diced chicken breasts will then be placed on a tray in the pet food freeze dryer. In this process, the pallet will be fed into the silo of the freeze dryer for cryogenic freezing, and the temperature will be reduced to about minus 40 degrees Celsius. At low temperatures, diced chicken breasts will be quickly frozen into solids.

After the diced chicken breast is frozen to meet the requirements, the warehouse of the pet food freeze-dryer begins to form a high vacuum environment, and the moisture in the frozen solid diced chicken breast is converted into gas and discharged through circulating temperature control. The whole process takes about 12~18 hours to ensure that the moisture in the diced chicken breast is completely sublimated and dry. Once the drying sublimation process is complete, the freeze dryer will automatically stop working and the diced chicken breasts will be removed.

The freeze-dried diced chicken breasts will be packed and sealed to keep them fresh and dry. Such packaging not only protects the food from external contamination, but also extends its shelf life. When using, you can choose the appropriate packaging size according to your needs to meet the edible needs of your pet.

)

)

)